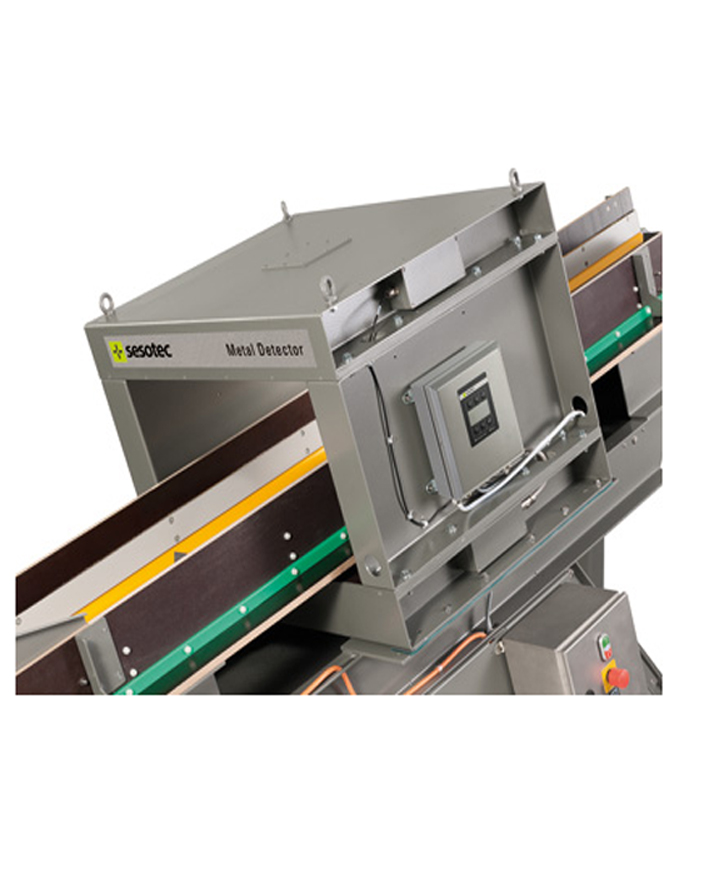

C-SCAN DLS

-

C-SCAN DLS

-

Detects magnetic and non-magnetic metal contamination, even when enclosed in product

-

Reduces expensive machinery failure and minimises production downtime

-

Ensures product quality

-

Prevents customer complaints

-

Break even within a very short period of time

Product description:

-

The split able tunnel detector DLS is used to analyse smalls and bulk materials on a conveyor belt or material chutes. Preferably used for high material. It detects all magnetic and non-magnetic metal contaminations (steel, stainless steel, aluminium) – even if enclosed in the product. On detection of metal, a signal device and a separation system can be activated or a signal can be send to process controlling.

Advantages:

-

To analyse small and bulk materials with material height over 100 mm

-

High scanning sensitivity to all metals

-

Easy installation on conveyors, no need to disconnect belt

-

The sturdy and solid design guarantees high noise immunity

-

Pre-installed parameters simplify operation

-

Auto-Set function for the improved compensation of external interference factors and for the active prevention of faulty activations

-

Operation mode "Alukomp": Compensation of aluminium coated foils (depending on foil thickness)

- Increased signal-to-noise-ratio towards electromagnetic pollution, vibrations and conveyor belt distortion

Split able metal detector for installation on conveyor belts and material chutes

Application Profile:

Operation: ● detects all magentic and non-magnetic metals

Inspection of: ● piece goods (incl. packed goods)

● bulk materials

Material flow: ● belt conveyors

● chutes

● vibration feeder

Benefits: