RAPID VARIO-FS

- Operation: detects and separates all magnetic and non-magnetic metals

- Inspection of: bulk materials

- Material flow: free-fall

- The RAPID VARIO-FS metal separator is used to inspect bulk goods under free-fall conditions. It detects all magnetic and non-magnetic metal contaminations (steel, stainless steel, aluminum, etc.), even when enclosed in the product. Metal contaminations are rejected through the “Quick Flap” reject unit.

- The RAPID VARIO-FS is used mainly in industries with low hygiene applications.

-

Detects and separates magnetic and non-magnetic metal contamination, even when enclosed in product.

-

Reduces expensive machinery failure and minimises production downtime.

-

Ensures product quality.

- Prevents customer complaints.

- Break-even within a very short period of time.

- Separation unit and product-contacting metal parts completely made of stainless steel 1.4301 (AISI 304).

- Low installation height; the metal separator can be easily fitted into existing pipeline systems.

- Separated detection and separation units:Free-fall height can be individually adjusted on site; Position of waste reject unit can be turned to match position of collecting tray.

- Standard Jacobs adaptors for inlet and outlet ensure quick, hassle-free installation.

- Auto-Set (auto-teach function) or manual pro-duct compensation (no fixed setting) for improved adaptation to the intrinsic conductivity of the product to be inspected.

- Pre-installed parameters for simplified operation.

- Enhanced signal-to-noise-ratio minimizing electromagnetic pollution and vibrations.

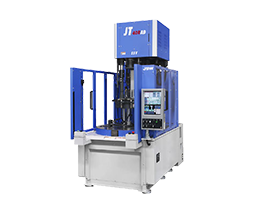

Metal Separator-RAPID VARIO-FS

Metal separator for free-fall applications

Application Profile:

Product Description:

Product Benefits:

Application Features: